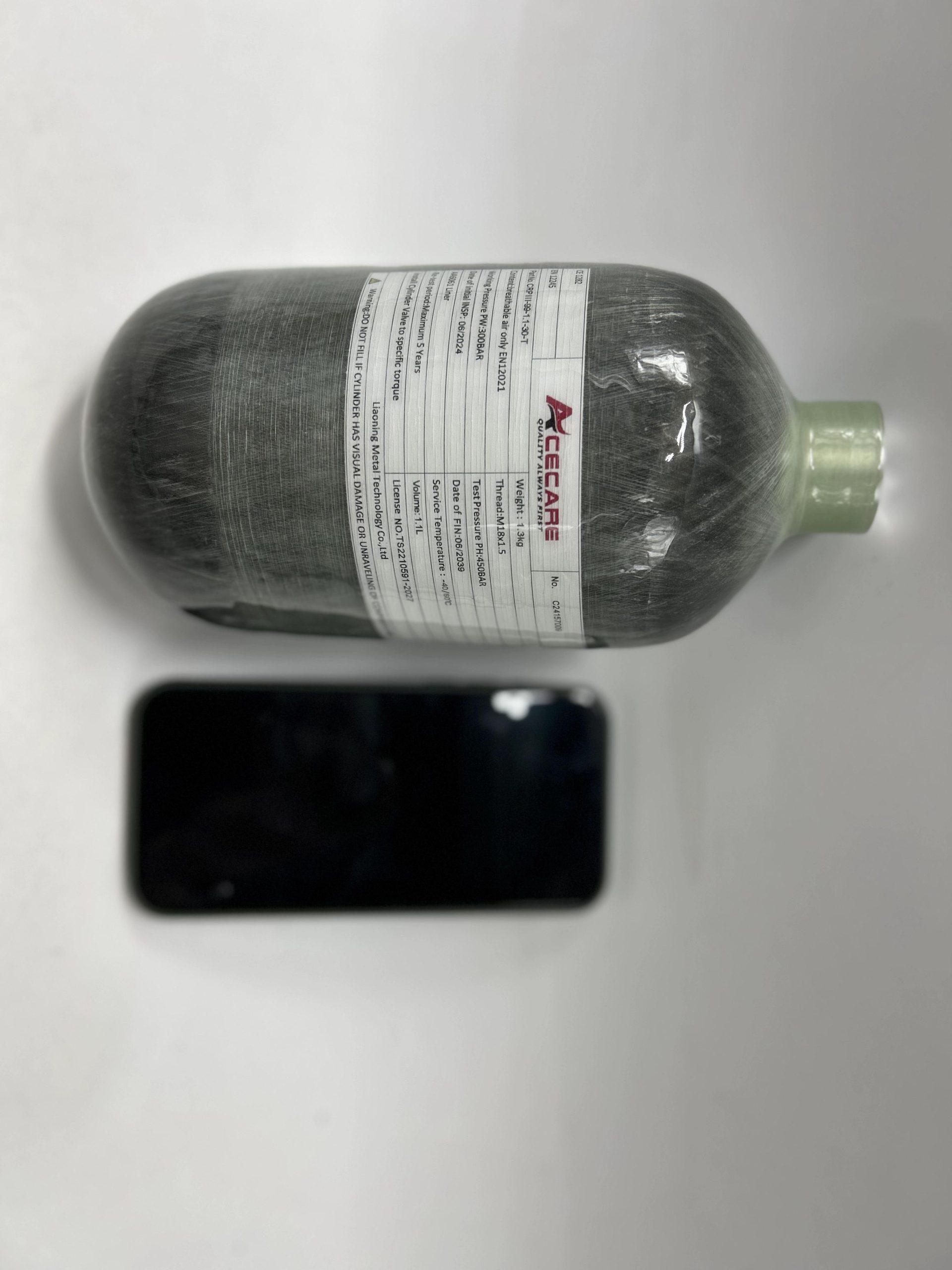

So you’ve invested in carbon fiber cylinders smart choice! These lightweight powerhouses are game-changers, but like any premium product, they need proper care to deliver their full value. I’ve spent years working with these materials, and I’m sharing what I’ve learned to help you get the most out of your purchase.

The Golden Rules: What NOT to Do

Before diving into maintenance procedures, let’s talk about what to avoid at all costs:

Look, I can’t stress this enough avoid exposing your carbon fiber cylinders to extreme temperatures. I once had a customer who left their cylinder in direct sunlight during a heatwave. The result? Compromised structural integrity that could have been avoided with some basic precautions.

Also, watch out for these common mistakes:

- Using harsh chemical cleaners (they’ll eat away at the protective coating)

- Dropping or subjecting cylinders to impact (carbon fiber is strong but can develop invisible damage)

- Ignoring even minor surface abrasions (small issues can become big problems)

Regular Inspection: Your First Line of Defense

I recommend setting calendar reminders for cylinder inspections—it’s something I do myself. Here’s what you should look for:

- Visual Inspection: Check for any visible cracks, fractures, or abrasions on the surface. Even hairline issues matter.

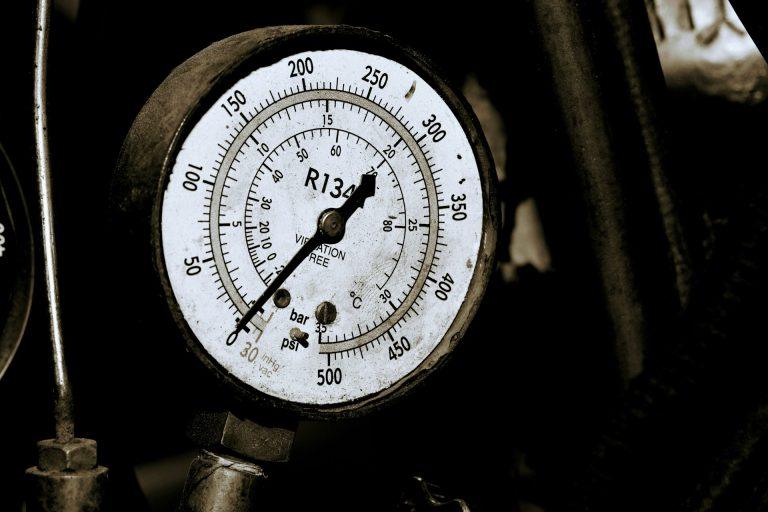

- Pressure Testing: If your cylinders are pressurized, regular pressure tests aren’t just recommended they’re essential. A slight pressure drop over time might indicate a developing issue.

- Connection Points: Pay special attention to areas where your cylinder connects to other equipment. These are stress points where problems often start.

Cleaning Protocol That Works

I’ve tried various cleaning methods over the years, and this simple routine works best:

- Wipe the cylinder with a soft, damp cloth to remove dust and debris.

- For stubborn dirt, use only mild soap diluted in water—nothing stronger.

- Dry thoroughly with a microfiber cloth to prevent water spots.

- Apply a specialized carbon fiber protectant (if recommended by your manufacturer).

Trust me, keeping it simple is key. Your cylinders don’t need fancy treatments just consistent, gentle care.

Storage Wisdom

The way you store your carbon fiber cylinders when not in use dramatically affects their lifespan. I learned this lesson the hard way when I stored some cylinders in my damp garage one winter.

Ideal storage conditions include:

- Climate-controlled environment (consistent temperature)

- Low humidity (moisture is the enemy)

- Away from direct sunlight

- Stored horizontally rather than standing (reduces stress points)

- Cushioned from hard surfaces

- Away from corrosive materials or chemicals

Transportation Tips

Whether you’re moving your cylinders between job sites or relocating your operation, transportation deserves special attention:

- Always use padded cases designed specifically for carbon fiber cylinders.

- Secure cylinders to prevent rolling or shifting during transport.

- Avoid stacking heavy items on top of cylinder cases.

- Consider vibration dampening materials for long transports.

When to Call in the Professionals

While regular maintenance can be handled in-house, there are times when professional assessment is necessary. I’ve seen too many people try to fix issues themselves only to make things worse.

Schedule professional inspections:

- After any impact event, even if no damage is visible

- At least annually for critical applications

- If you notice any performance changes

- When certification renewal is required

Real Talk About Lifespan Expectations

Let’s be realistic carbon fiber cylinders aren’t immortal, despite their premium quality. With proper care, most high-quality cylinders should deliver 10-15 years of reliable service, though this varies by application intensity and environmental conditions.

Signs it might be time for replacement:

- Surface weave becoming visible through the coating

- Any deformation of the cylinder shape

- Repeated pressure loss issues

- Manufacturer’s recommended replacement timeline

Final Thoughts

I’ve seen the difference proper maintenance makes. Two identical cylinders can have drastically different lifespans based solely on how they’re maintained. The small investment of time in proper care pays tremendous dividends in equipment longevity.

Remember, your carbon fiber cylinders represent cutting-edge technology designed to give you advantages in weight, strength, and performance. Treat them with the respect they deserve, and they’ll remain valuable assets for years to come.

Have questions about your specific carbon fiber cylinders? Feel free to contact our team we’re always happy to provide personalized maintenance guidance.