I still remember my first day working with high-pressure gas cylinders. My mentor pointed to a cylinder and told me, “That’s not just a container—it’s a potential rocket if mishandled.” That healthy respect for cylinders has stayed with me throughout my career, especially when it comes to carbon fiber cylinders, which combine incredible strength with lighter weight but require specific handling knowledge.

Whether you’re a seasoned professional or new to working with these advanced composite cylinders, understanding the regulatory landscape and proper handling procedures isn’t just about compliance—it’s about keeping yourself and everyone around you safe.

The Regulatory Landscape: More Than Just Bureaucracy

Let’s be honest—regulatory standards can seem like alphabet soup. ISO, DOT, CE, UN, TC… it’s easy to tune out. But behind each of these acronyms are hard-learned lessons, often written in response to incidents that cost lives or equipment.

Key International Standards You Need to Know

Department of Transportation (DOT) Requirements

In the United States, the DOT regulates the transportation of pressurized cylinders through specifications like:

- DOT-CFFC: Specific to fully wrapped carbon fiber reinforced aluminum lined cylinders

- DOT-SP: Special permits for designs that meet safety requirements through alternative means

- 49 CFR 173.301: General requirements for shipment of compressed gases

The DOT requirements focus particularly on design qualifications, periodic retesting, and proper marking. I’ve seen shipments rejected and businesses fined because cylinders didn’t meet these requirements—even when the cylinders themselves were perfectly sound.

ISO Standards: The Global Framework

ISO standards provide internationally recognized guidelines for cylinder design, testing, and manufacturing:

- ISO 11119-2: Specification for fully wrapped carbon fiber cylinders with metal liners

- ISO 11119-3: Specification for fully wrapped cylinders with non-metallic liners

- ISO 11623: Periodic inspection and testing requirements

What makes ISO standards particularly valuable is their focus on the entire lifecycle of a cylinder—from design to retirement.

European CE Marking

For those doing business in Europe, CE marking indicates compliance with the Pressure Equipment Directive (PED) and often includes:

- Structural requirements specific to the European market

- Documentation standards for material traceability

- Third-party verification processes

I once worked with a company that had to recall an entire shipment because they assumed their DOT certification would be sufficient for European markets. That expensive mistake taught them the importance of understanding regional requirements.

Other Critical Standards

Depending on your specific application and location, you may also need to comply with:

- CGA (Compressed Gas Association) guidelines for safe practice

- TPED (Transportable Pressure Equipment Directive) for European transport

- TC (Transport Canada) requirements for Canadian markets

- AS/NZS standards for Australia and New Zealand

Transportation Regulations: Moving Cylinders Safely

Transporting carbon fiber gas cylinders requires specific precautions—both for regulatory compliance and practical safety.

Road Transport Best Practices

When transporting cylinders by road:

- Secure cylinders upright when possible, using appropriate restraints that prevent movement in any direction.

- Ensure proper ventilation in the vehicle—I personally ensure windows can be opened or that there’s some form of active ventilation.

- Never transport cylinders with regulators attached. Always remove regulators and install protective valve caps.

- Carry appropriate documentation, including safety data sheets for the gas contents and cylinder certification papers.

- Use hazard placards on your vehicle when required by regulations.

I learned about ventilation importance the hard way when a small leak in a cylinder being transported created a potentially dangerous situation in a closed vehicle on a hot day—something I’m now hypervigilant about preventing.

Air Transport Considerations

Air transportation of pressurized cylinders is highly regulated and often restricted. If you must ship by air:

- Only cylinders specifically tested and marked for air transport can be used

- Pressure must typically be reduced below maximum working pressure

- Additional documentation and declarations are required

- Advanced notification to the carrier is often necessary

As someone who regularly ships equipment internationally, I can tell you that air transport regulations for cylinders are among the most stringent in the industry—and with good reason.

International Shipping Challenges

When shipping cylinders internationally, plan for:

- Customs clearance requirements specific to pressurized vessels

- Potentially different certification requirements at destination

- Translation of safety information and markings

- Longer transit times that may require additional testing upon arrival

I recommend working with shipping specialists who have specific experience with pressurized cylinders when crossing international borders.

Safe Handling: The Day-to-Day Practices That Matter

Beyond regulations, the way you handle cylinders daily has the biggest impact on safety.

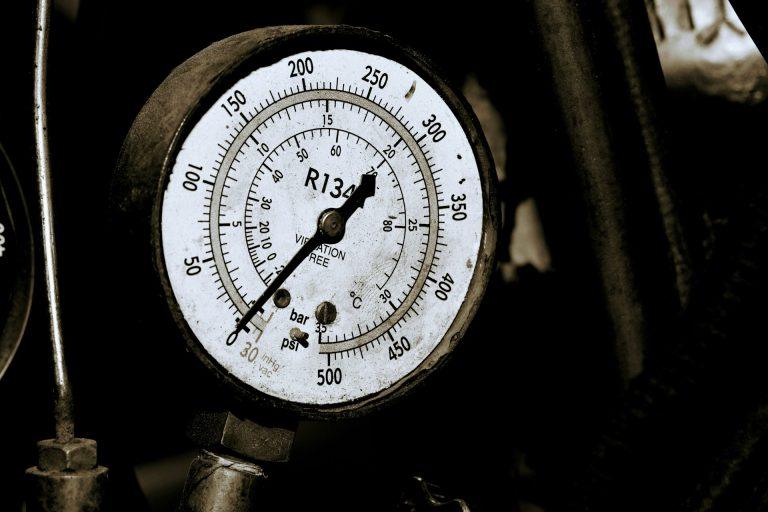

Charging (Filling) Procedures

When filling carbon fiber cylinders:

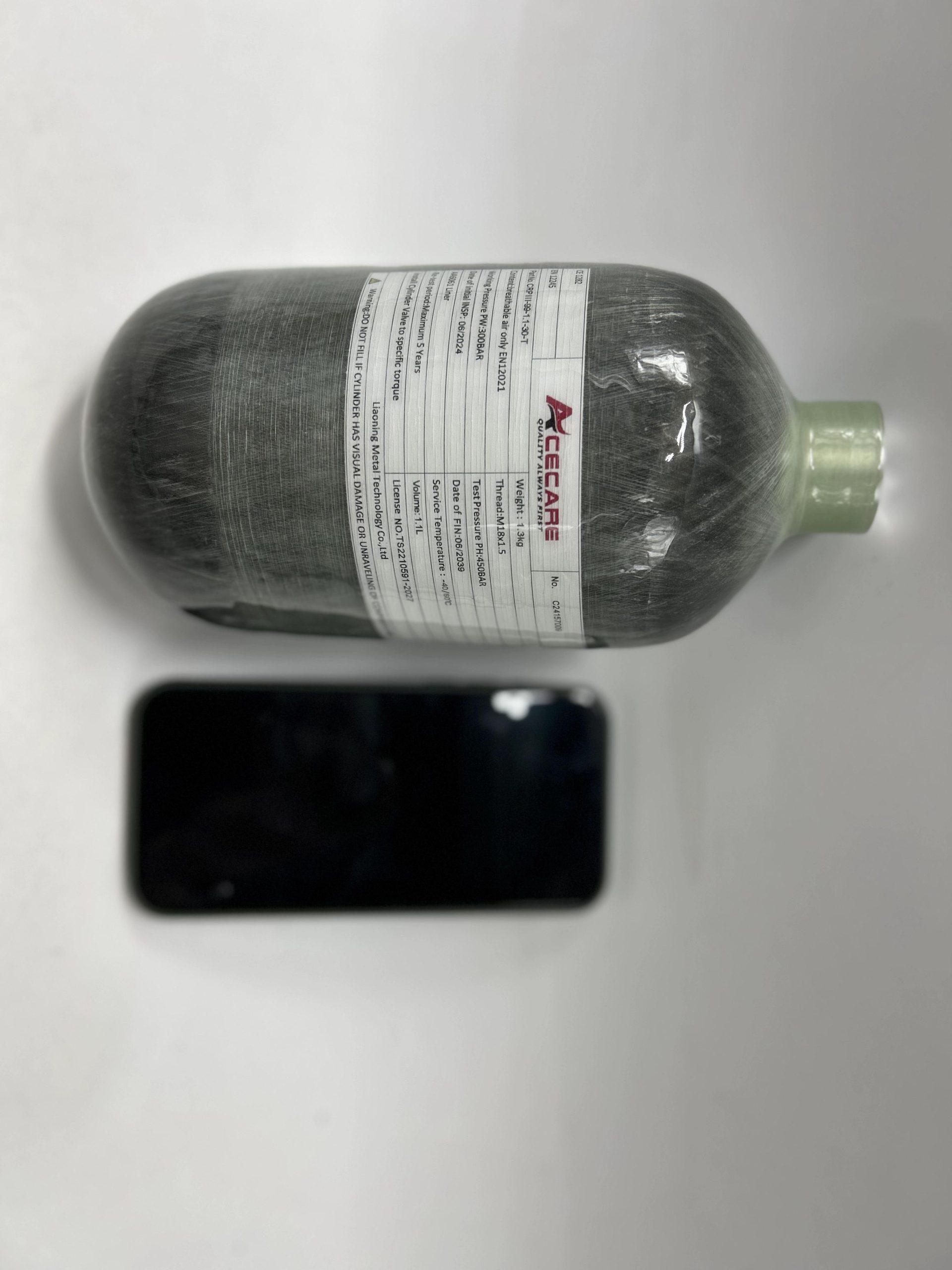

- Visual inspection first: Before filling, I always check for visible damage, especially around neck threads and the composite surface for any signs of impact, abrasion, or delamination.

- Verify certification dates: Never fill an out-of-test cylinder—it’s both illegal and dangerous.

- Control fill rate: Carbon fiber cylinders should be filled slowly to prevent heat buildup. I aim for no more than 300-500 PSI per minute.

- Monitor temperature: The cylinder temperature should never exceed the manufacturer’s maximum rated temperature during filling. I keep a non-contact thermometer handy for this.

- Never exceed rated pressure: This seems obvious, but pressure creep during temperature equalization can push borderline fills over the limit.

A colleague once tried to “top off” a cylinder just a bit beyond its rated pressure. The minute he saved in filling time cost days of downtime when the cylinder had to be removed from service and recertified.

Discharging Safety Protocols

When emptying or using gas from cylinders:

- Control discharge rate: Rapid discharge can cause dangerous cooling of both the cylinder and the gas.

- Use appropriate regulators rated for both the gas type and pressure range of your cylinder.

- Never completely empty composite cylinders of certain gases (especially air)—some minimum pressure helps prevent internal contamination.

- Monitor downstream equipment for pressure ratings—just because your cylinder can handle high pressure doesn’t mean everything connected to it can.

Everyday Handling Tips

These simple practices prevent the most common incidents:

- Always use cylinder carts designed for secure transport when moving cylinders.

- Never roll cylinders on their sides—carbon fiber cylinders can be damaged by this common practice that might be acceptable for steel cylinders.

- Establish designated storage areas away from heat sources, electrical equipment, and flammable materials.

- Use cylinder stands or wall restraints to prevent tipping.

- Keep valve protection in place when cylinders aren’t in active use.

Leak Prevention and Detection: Small Leaks, Big Problems

Even minor leaks can create major hazards over time, especially in enclosed spaces.

Prevention Strategies

To minimize leak risks:

- Use appropriate thread sealants compatible with both your gas type and carbon fiber cylinders.

- Apply proper torque to connections—neither too tight (which can damage threads) nor too loose.

- Replace O-rings and seals according to maintenance schedules, not just when they fail.

- Protect valve threads when cylinders are in storage or transit.

Detection Methods

For regular leak checks:

- Soap solution testing: Apply bubble solution to connections and watch for bubble formation—still one of the most reliable methods I use regularly.

- Electronic leak detectors: Particularly useful for inert gases that might otherwise go undetected.

- Pressure monitoring: Track pressure drops over time in static systems.

- Ultrasonic detection: Advanced but increasingly affordable option for identifying small leaks by the sound they make.

I make it a habit to perform a full leak check after any connection change, no matter how minor. That practice has caught numerous potential problems before they became actual incidents.

Training Requirements: Knowledge Saves Lives

Proper training isn’t just a regulatory checkbox—it’s essential protection.

Essential Training Elements

Comprehensive cylinder handling training should include:

- Recognition of cylinder types and their specific requirements

- Understanding of pressure concepts and hazards

- Proper handling and transport techniques

- Emergency response procedures

- Documentation and record-keeping requirements

Retraining and Updates

Safety knowledge needs refreshing:

- Annual retraining is standard in most industries

- Update training whenever regulations change

- Conduct specific training when new equipment is introduced

- Document all training for both compliance and liability protection

I’ve found that brief monthly safety talks focused on cylinder handling help keep safety awareness high between formal training sessions.

Emergency Response: When Things Go Wrong

Despite all precautions, emergencies can occur. Being prepared makes the difference.

Common Emergency Scenarios

Be prepared for these potential situations:

- Leaking cylinder: Established isolation protocols, ventilation procedures, and when evacuation is necessary.

- Physical damage to cylinder: Response depends on damage severity—from increased monitoring to immediate area evacuation.

- Fire exposure: Procedures for cylinders exposed to fire, including emergency services notification with specific information about cylinder contents and pressures.

- Transportation incidents: Response plans for accidents during cylinder transport, including public safety measures.

Emergency Equipment

Have these items readily accessible:

- Appropriate fire extinguishers

- Personal protective equipment

- Cylinder containment devices (for small cylinders)

- Emergency contact information for manufacturers and regulatory authorities

- Gas-specific neutralization or containment materials when applicable

Real-World Implementation: Making Safety Practical

Safety programs fail when they’re too complicated to follow consistently. Here’s how to make cylinder safety part of your daily routine:

- Create simple checklists for regular handling activities.

- Establish clear visual indicators for cylinder status (in-test/out-of-test, full/empty, etc.).

- Designate specific responsibility for cylinder management rather than making it everyone’s job (which often means no one’s job).

- Incorporate cylinder checks into existing processes rather than creating separate procedures.

- Make reporting concerns easy and non-punitive to encourage early problem identification.

The Bottom Line: Safety Is Good Business

Beyond the obvious importance of preventing injuries, proper cylinder handling delivers business benefits:

- Extended cylinder life and reduced replacement costs

- Lower insurance premiums through demonstrated safety practices

- Fewer operational interruptions from equipment problems

- Regulatory compliance without last-minute scrambling

- Enhanced reputation with customers and partners

Final Thoughts

After two decades working with pressurized systems, I’ve learned that cylinder safety isn’t about fear—it’s about respect. Carbon fiber cylinders are engineering marvels that enable countless applications through their lightweight strength, but they require knowledge and care to use safely.

The time you invest in understanding regulations, implementing proper procedures, and training personnel pays dividends in both safety and operational efficiency. In my experience, the organizations with the best safety records are also the ones with the most productive operations—because attention to detail matters in both areas.

Have questions about your specific carbon fiber cylinder applications? Contact our team for guidance tailored to your needs and uses. Your safety is our priority.