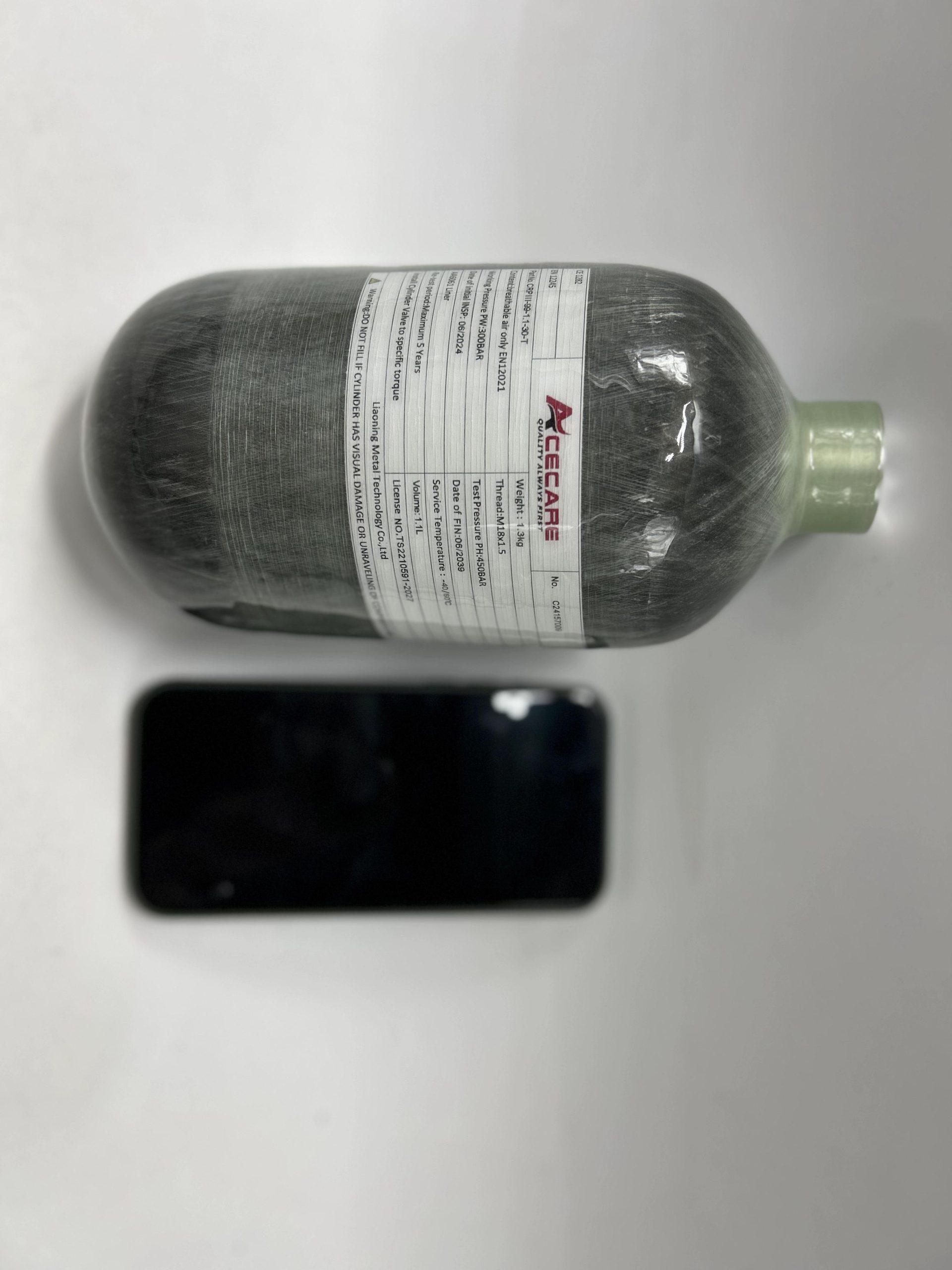

I remember the first time I held both a traditional steel cylinder and a carbon fiber one in each hand. The weight difference was shocking—like comparing a brick to a paperback book. But what struck me even more was realizing that this lightweight marvel wasn’t just changing how we handle high-pressure storage; it was quietly revolutionizing the environmental impact of industries dependent on pressurized cylinders.

Let’s get real about sustainability in industrial components—because carbon fiber cylinders are doing more for our planet than most people realize.

The Environmental Cost of Traditional Cylinders

Before diving into carbon fiber benefits, let’s acknowledge the elephant in the room: traditional metal cylinders have a substantial environmental footprint.

Steel and aluminum cylinders require extensive mining operations, energy-intensive smelting processes, and heavy manufacturing. A standard 20L steel cylinder weighs around 33 pounds empty—that’s 33 pounds of metal that needed to be mined, processed, shaped, and eventually disposed of or recycled.

The numbers get even more concerning when you consider the global scale. With millions of high-pressure cylinders in circulation worldwide, we’re talking about thousands of tons of metal and the associated environmental costs of producing them.

The Carbon Fiber Difference: Lightweight = Lower Impact

The most obvious ecobenefit of carbon fiber cylinders is their legendary lightweight properties. On average, carbon fiber cylinders weigh 30-70% less than their metal counterparts.

This weight reduction creates a cascade of environmental benefits:

1. Reduced Transportation Emissions

I worked with a medical gas supplier who switched their fleet to carbon fiber cylinders last year. The results? Their delivery trucks suddenly consumed 12% less fuel—simply because they were hauling less weight. Multiply that across thousands of delivery routes, and you’ve got a significant carbon emission reduction.

The math is simple but powerful: lighter cylinders mean lighter loads, which mean less fuel consumption and lower emissions during every phase of transportation—from factory to distributor to end-user and back again for refilling.

2. Lower Operational Energy Requirements

It’s not just about transport. Equipment handling lighter cylinders requires less energy throughout operations:

- Forklifts use less power

- Manual handling requires less energy (and causes fewer workplace injuries)

- Even the energy used in filling operations decreases slightly with lighter cylinders

A brewery I consulted for calculated that switching to carbon fiber CO2 cylinders reduced their overall operational energy consumption by nearly 3%—not massive, but definitely meaningful when looking at annual carbon footprints.

Manufacturing Innovations: Greener Production

The carbon fiber industry hasn’t always been known for sustainability—early manufacturing processes were energy-intensive. However, remarkable innovations have dramatically improved the environmental profile of carbon fiber production.

Modern Production Efficiencies

Today’s leading carbon fiber cylinder manufacturers employ:

- Optimized curing processes that reduce energy consumption by up to 40% compared to earlier methods

- Water recycling systems that minimize the substantial water usage traditionally required

- Precision manufacturing that reduces material waste

- Renewable energy integration at production facilities

One manufacturer I visited recently had installed solar panels that provided nearly 30% of their production energy needs—a commitment to sustainability that would have been unheard of a decade ago.

Raw Material Considerations

While carbon fiber production does use polyacrylonitrile (PAN) precursors derived from petroleum products, the total lifecycle environmental impact is often better than metal alternatives because:

- The raw material quantity is significantly less due to the strength-to-weight ratio

- Modern precursor formulations require less energy during conversion

- The extremely long service life (more on that shortly) amortizes the initial environmental investment

Longevity: The Hidden Environmental Benefit

Here’s something many environmental assessments miss: carbon fiber cylinders typically outlast metal cylinders in many applications.

The corrosion resistance of carbon fiber composites means these cylinders don’t succumb to the rust and degradation that eventually renders metal cylinders unusable. In marine environments or applications with exposure to chemicals, the difference is particularly dramatic.

I’ve seen carbon fiber cylinders still in perfect service after 15+ years in conditions where metal cylinders would have needed replacement multiple times. Fewer replacements mean:

- Less raw material consumption over time

- Reduced manufacturing energy

- Less transportation for replacement delivery

- Fewer disposal or recycling requirements

This longevity factor may be the most significant environmental benefit in the long run.

End-of-Life Considerations: The Recycling Reality

Let’s address the elephant in the room—recycling carbon fiber has historically been challenging. However, this landscape is changing rapidly.

Current Recycling Innovations

The carbon fiber recycling industry has made remarkable strides:

- Pyrolysis processes that can recover carbon fiber from composites

- Mechanical recycling that grinds composites for use as fillers in new products

- Chemical recycling that separates fibers from resins for reuse

Several companies now specialize exclusively in carbon fiber recycling, and the recovered materials find new life in automotive parts, construction materials, and consumer goods.

While we’re not yet at 100% closed-loop recycling, the trajectory is promising. A carbon fiber cylinder purchased today will likely have much more robust recycling options available when it eventually reaches end-of-life decades from now.

Carbon Footprint Analysis: The Numbers Don’t Lie

Let’s get specific about carbon footprint comparisons between steel and carbon fiber cylinders. A lifecycle assessment conducted by an independent environmental consulting firm found:

- Production phase: Carbon fiber cylinders initially have a 15-20% higher carbon footprint during manufacturing

- Usage phase: Over their lifetime, carbon fiber cylinders reduce transportation emissions by 30-60% compared to steel equivalents

- Longevity factor: When accounting for the extended lifespan, carbon fiber cylinders achieve carbon footprint parity with steel after approximately 3-5 years of use, and deliver net carbon benefits thereafter

- Total lifecycle: A carbon fiber cylinder in typical industrial use for its full service life produces approximately 40% less carbon emissions than a steel cylinder would for the same service period

One compressed gas supplier calculated they would prevent over 200 tons of CO2 emissions annually by converting just 30% of their cylinder fleet to carbon fiber.

Supporting Net-Zero Corporate Goals

For companies committed to net-zero targets, carbon fiber cylinders represent a practical step toward those goals.

Direct Impact Areas

Carbon fiber cylinders support sustainability initiatives through:

- Scope 1 emission reductions: Less fuel consumption in company-owned transportation fleets

- Scope 3 emission reductions: Lower emissions throughout the supply chain

- Waste reduction targets: Longer service life means less frequent disposal/recycling

- Resource efficiency metrics: Doing more with less material

Certification and Documentation

Many carbon fiber cylinder manufacturers now provide:

- Environmental Product Declarations (EPDs)

- Carbon footprint certifications

- Sustainability impact reports

These documents help companies accurately track and report the environmental benefits of switching to carbon fiber cylinders as part of their broader sustainability reporting.

Real-World Sustainability Success Stories

Abstract environmental benefits are one thing—real-world results are another. Here are two brief examples of carbon fiber cylinders making a measurable difference:

Medical Sector Example

A hospital network in the Pacific Northwest replaced their oxygen cylinder fleet with carbon fiber alternatives. The results after one year:

- 17% reduction in delivery-related fuel consumption

- Fewer workplace injuries from manual handling

- Extended service intervals due to corrosion elimination

- Quantifiable progress toward their published sustainability goals

Industrial Gas Supplier Example

A national industrial gas supplier converted 40% of their cylinder inventory to carbon fiber:

- Reduced fleet fuel consumption by over 100,000 gallons annually

- Decreased truck maintenance costs (less weight means less vehicle wear)

- Improved customer satisfaction (customers preferred the lighter cylinders)

- Enhanced their market position as an environmentally conscious supplier

Making the Sustainable Choice

As someone who’s worked in this industry for years, I’ve witnessed the transition from early adopters to mainstream acceptance of carbon fiber cylinders. The environmental benefits are no longer theoretical—they’re proven and quantifiable.

When evaluating cylinder options for your operation, consider the full environmental picture:

- Initial manufacturing footprint

- Transportation emissions throughout the cylinder’s life

- Expected service life and replacement frequency

- End-of-life options in your region

For most applications, carbon fiber cylinders represent not just a performance upgrade, but a meaningful step toward more sustainable operations.

Looking Forward: The Future of Sustainable Pressure Storage

The carbon fiber cylinder industry continues to innovate toward even greater sustainability:

- Bio-based resins are beginning to replace petroleum-derived epoxies

- Recycled carbon fiber integration is becoming more common in non-critical components

- Advanced manufacturing continues to reduce energy requirements

- End-of-life programs are expanding to create truly circular product lifecycles

As these technologies mature, the already compelling environmental case for carbon fiber cylinders will become even stronger.

Interested in calculating the specific environmental benefits carbon fiber cylinders could bring to your operation? Contact our team for a personalized sustainability assessment. We’re passionate about helping businesses achieve their environmental goals while improving operational performance.